Shaping Solutions: Exploring Loureiro’s Use of Printed Parts

September 26th, 2025

Bringing innovation to the jobsite with custom, on-demand solutions through 3D printing

Loureiro’s EHS team is turning to 3D printing as a faster, cleaner, and more flexible way to create custom machine guards and problem-solving components in the field. By combining quick prototyping with durable materials, printed parts have already improved safety, reduced waste, and delivered innovative solutions across manufacturing, wastewater, and construction projects. This growing capability reflects Loureiro’s culture of Passionate Ingenuity and opens the door to new applications that meet client needs with speed and precision.

Every machine safeguarding project comes with its own specific requirements. No two shop floors look alike, and no two machines present hazards in quite the same way. Loureiro’s EHS team is often called in to design custom guards that reduce risk without slowing down production. Traditionally, that has meant cutting and bending materials on site — effective, but messy, time-consuming, and difficult to adjust if conditions changed.

When one client asked if there was a faster, cleaner way to achieve the same outcome, the team saw an opportunity. Could additive manufacturing provide the precision and flexibility that conventional fabrication lacked? That question set Loureiro on a path to bring 3D printing into the field, turning an emerging technology into a practical tool for solving everyday problems.

Innovation in Practice

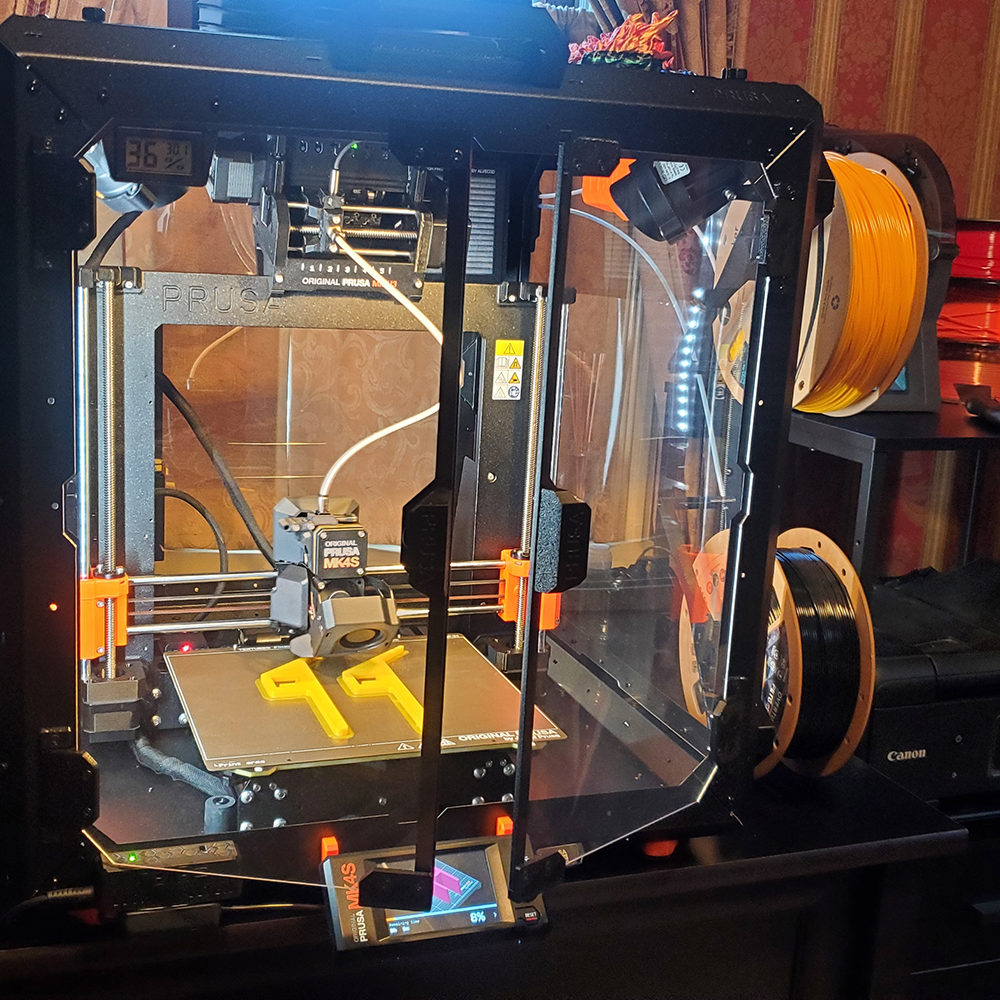

Superintendent Jay Varney was quick to see how 3D printing could strengthen Loureiro’s approach. The team invested in a compact FDM printer from Prusa Research, known for its portability and versatility, and began experimenting with machine guarding.

“We wanted a way to test ideas quickly without all the dust and waste that comes from cutting on site,” Jay explains. “With a 3D printer, you can produce a prototype in minutes, check the fit, and refine the design until it’s exactly what you need.”

What started as an experiment in prototyping soon became more. In certain cases, the printed parts were durable enough to remain in service as the finished guard, giving Loureiro a new way to deliver safety solutions directly in the field.

The Details

The workflow blends field ingenuity with digital tools. Crews often begin with a quick cardboard template to visualize a guard and get operator feedback. From there, dimensions are measured with calipers and translated into CAD software such as SOLIDWORKS or Fusion 360. The model is exported as an STL file, then processed through slicing software that determines thickness, strength, and infill.

From template to finished print, the turnaround can be measured in hours rather than days. Simple profiles can be printed right on site for immediate testing, while larger runs can be left to build overnight. This speed and adaptability allow Loureiro to deliver safer, better-fitting solutions without disrupting operations.

In the Field

The benefits of printed parts have already shown up across applications.

On a roller line where in-running nip points posed a serious hazard, the team designed a rotating “flipper” guard that connects to a safety-rated shaft switch. If contacted, the paddle rotates just a few degrees, shutting down the machine and signaling a fault. By printing the guard in modular sections, Loureiro created a flexible design that can be stacked to match any machine width, providing one solution that serves many different applications.

In wastewater operations, printed parts helped solve a different problem. Engineers calibrating long, heavy pH probes were struggling with clearance issues that left fragile sensor tips vulnerable to damage. Loureiro printed small baffles that protected the probe, allowed water to flow across the membrane, and doubled as a stand during calibration. Two simple parts reduced operator strain and prevented damage to probes that can cost hundreds of dollars each.

Even in construction, printed parts have proven their worth. Instead of cutting steel brackets from sheet metal to test hole spacing, the team now prints templates to check fit and alignment. Once verified, the CAD model is sent for fabrication in steel or aluminum, saving time and avoiding wasted material.

These examples also highlight the flexibility of material choice. PETG filament, known for its durability and resistance to oils and coolants, has become a reliable standard for machine guarding. For higher-load applications, carbon-fiber-filled filaments add strength. And in healthcare or clean environments, specialty antimicrobial materials can be deployed. Each part is tailored to its setting, reinforcing Loureiro’s ability to deliver the right solution for the job.

Looking Ahead

Printed parts have already moved from experimental prototypes to functional safety guards and problem-solving components. Their role within Loureiro’s toolbox is expanding as new applications surface across service lines.

“It’s nice to be able to stand on your own two feet with solutions that don’t exist anywhere else,” Jay says.

Additive manufacturing has become another tool that supports Loureiro’s culture of Passionate Ingenuity. It combines technical skill with practical creativity to meet client needs in smarter ways. Colleagues who see potential uses for printed parts in their own work are encouraged to connect with the EHS team and explore how this capability can support their projects.