Hanwha Aerospace: A Study in Teamwork Leading to Wins

September 15th, 2023

A former operating facility owned by Hanwha Aerospace in Agawam, MA was lacking direction. With no real vision for getting the site through the complex Massachusetts regulatory process to closure, Loureiro was brought in to develop a plan for this stranded asset, including a comprehensive strategy for removing contaminants from the ground.

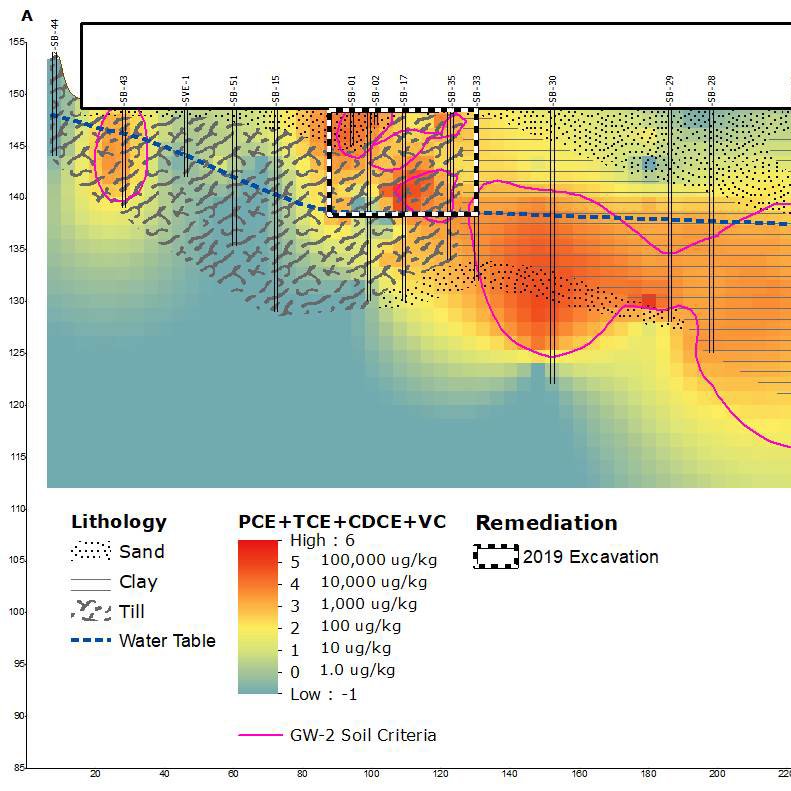

Plagued by chlorinated solvents beneath the building and parking lot, Hanwha came to Loureiro seeking leadership and innovative ideas for addressing the issues at the site in a cost effective and time sensitive manner.

The existing remedy at the site involving soil vapor extraction wasn’t working as the process was not designed to pull contaminants out of the groundwater. Although the existing remedy functioned to prevent vapor migration, it did not address the underlying problem.

Loureiro needed to develop a strategy to control the groundwater plume and its potential impact on not only the existing tenants renting the facility, but the surrounding residential and commercial properties.

“Figuring this out has been the most fun I’ve had in a while,” says Vice President of Environmental Assessment Kate Engler. “We would have a lot of brainstorming sessions and progress meetings and everyone’s level of expertise showed up to help develop a strategy. I couldn’t do this alone. No single person could lead it. We came together as one.”

Following an internal strategy session which engaged all of Loureiro’s pertinent in-house expertise - in the Massachusetts regulatory environment, vapor intrusion and hydrogeology realm - the team developed three unique paths forward - ranging extensively in schedule, budget and complexity - for Hanwha’s consideration:

- An in-situ thermal remediation option to destroy harmful chemicals in soil and groundwater using heat

- A traditional option that would attack the actual source of the contamination in a less aggressive manner

- A barrier option that would remediate the plume at the downgradient edges and prevent off-site migration

The first potential solution, dubbed the “nuclear option” involved two to three years of thermal remediation, leaning heavily on XDD’s design expertise. This option presented the fastest path to a solution, but was cost prohibitive.

The second option outlined a more traditional, less aggressive approach as compared to thermal remediation – a strategy that involved attacking the actual source of the contamination that offered a middle ground in terms of time and cost associated with the techniques.

Ultimately, it was the third and final strategy that Hanwha opted to move forward with, which involved the design of a Zero Valent Iron (ZVI) barrier. ZVI is a remedy for harmful pollutants in both groundwater and wastewater that functions as a reductant, employed to break down or isolate contaminants and remediate a groundwater plume as it intercepts the barrier during migration. This option balances time and cost.

The process involves developing a grid with overlapping points that connect to make a barrier, and injecting ZVI into “hotspots” along the grid where it becomes a part of the soil matrix. This creates a physical barrier that stays for several years and involves occasional refreshes.

“Choosing the barrier approach instead of directly attacking the source area relies on natural degradation,” Kate says. “We study how quickly the groundwater moves and determine if there are naturally occurring bacteria that can attenuate the source material as the plume migrates further from the source area.”

In simple terms, Kate equates the ZVI approach to using a water purifying cartridge, similar to what one might have in their home.

“It’s a similar concept,” she says. “By the time the plume travels to the down gradient edge, the barrier will remediate the plume as it flows through.”

With a plan in place, the next phase of the project involves designing the barrier system. Loureiro will take soil and groundwater samples and perform a chemical analysis to determine the optimal solution.

Collaborating with her team members has made the early stages of this project incredibly rewarding for Kate, as they worked together on figuring out a preferred solution for a new client by applying the entire team’s collective expertise.

“XDD has done some similar ZVI treatments for clients in the past that have worked successfully,” Kate says. “Applying the talents within our different divisions to design a solution has proven that we can come together to solve complex problems that present major obstacles for our clients.”

Loureiro’s ZVI barrier design and implementation is expected to bring the site to an acceptable form of closure by 2026, adhering to the time frames and expectations of the Massachusetts Department of Environmental Protection.

Clients like options - and to that end, we outlined the costs and benefits associated with a variety of solutions to address the challenges at this particular site. With streamlined coordination and a collaborative approach, we look forward to future opportunities to support Hanwha with strategies for their other sites and business units located throughout our geographic footprint.